-

Posts

153 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Calendar

Posts posted by Fin

-

-

-

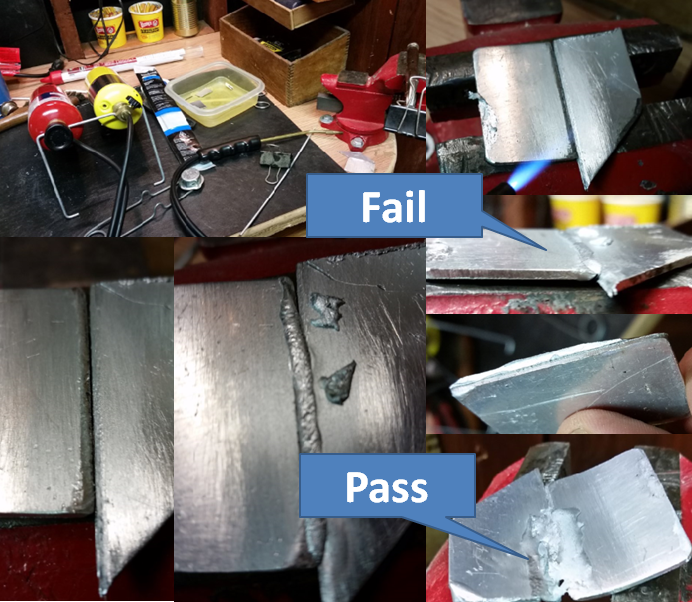

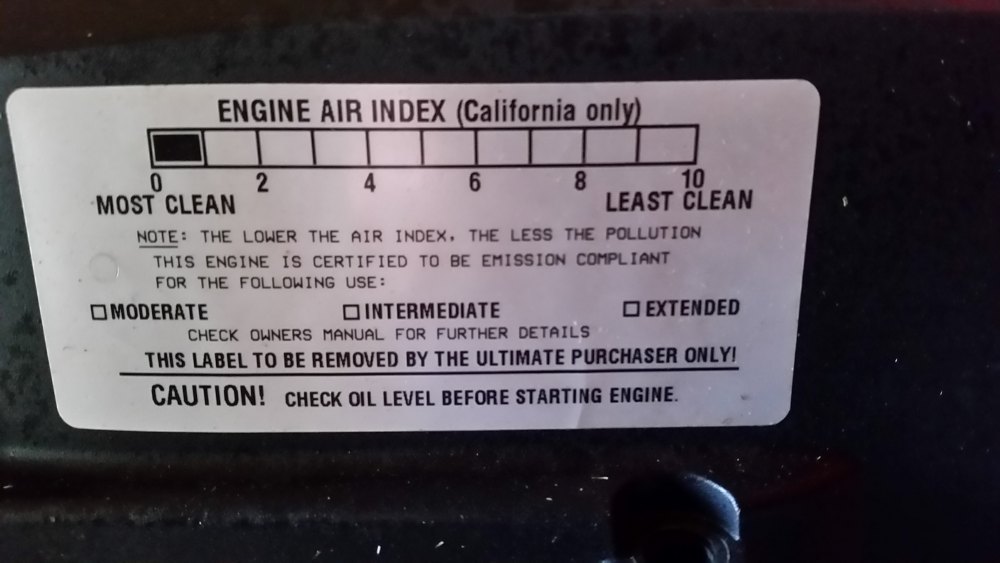

My first brazing attempt with AL-3. I also bought some Alumiweld from Harbor Freight, but the AL-3 seemed to do the trick.

I saw a guy preheat his block in a gas BBQ. I don't know if that is necessary, but from my knowledge of microchips and heatsinks it sounds like a damn good idea.

Now I just need to unbolt the block from the frame and put it in my wife's oven and pre-heat it to 400F without her being home and knowing about it.

Any comments and suggestions is appreciated, including excuses for the Mrs if she finds out.

-

20 hours ago, wolfeman28 said:

Be careful with map gas on the cast aluminum. Not all castings are made the same and some will start to melt before you can even get your filler to wet out and stick. Watch the heat in thin areas.

Thanks for telling me this. I'm just getting to know the material and the use of AL-3 and Alumiweld. On a practice piece I see exactly what you are saying. I melted part of the aluminum. Ouch!

-

-

4 hours ago, Wandering Soul said:

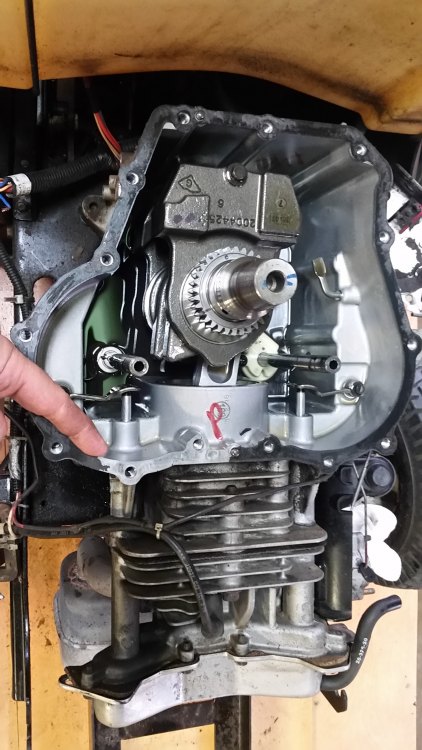

As long as you didn't disturb the cam gears timing will be where it needs to be. At one time Kohler offered on line manuals you could down load in PDF for all their engines. Try calling 800.544.2444 and ask them if they still offer those. Has torque specs, illustrations, and assembly steps right down to the bare crankcase.

Thanks... I appreciate your support. I'll definitely look up the PDFs.

-

28 minutes ago, Wandering Soul said:

The old loose cover bolt trick. How old is that motor? Kohler has all but admitted they had assembly problems. Just wasn't torqued right. That puller you brought is good for steering wheels and other stuff.

As long as you got the cover off, get a new seal where the crank comes up through. As long as you've got the flywheel off...

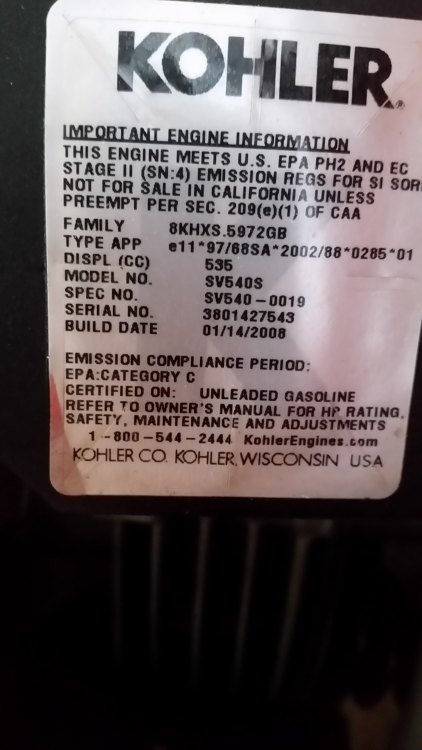

The engine is a 2008.

I'll probably never use the puller again, but it's good to know that I can use it for many other things.

And I'm glad you mentioned the seal.

A friend of mine said go get a gasket and not use the JB Sealer. You echoing that convinces me to go get the right part.

I'm concerned about the timing when I put it all back together.

I'm glad I took a lot of pictures. Hopefully that will help. -

Alright... this is the first engine I ever opened... I don't think I'll every buy another Kohler if I can help it. One crummy bolt was loose and because of it the block cracked.

For the future, if there's a future for this engine, I might be able to get to the bolt to tighten it without removing the fly wheel.

As for Kohler to know that this design flaw exists on every vertical shaft engine of their's for years and not address the problem in my opinion says a lot about Kohler. I never had problems like this with Briggs&Stratton engines.

For this project I had to buy a puller, another first, and discover if the bolts are standard or metric. Lucky me... this entire lawn tractor is mixed.

-

With so many options to choose from and the reasons for not have one is diminishing rapidly I have to ask:

1) What action cam are you using with your bike today?

2) What action cam do you wish you had instead?

3) What available options do you like most now and what do you want to see in the future?

4) And why?

-

3 hours ago, blue03636 said:

That was back in 2012/13.

Whatever became of that? -

12 hours ago, magley64 said:

There are a few challenges with implementation of an engine like this... Rotating surfaces, dynamic seals, etc... And the performance difference doesn't amount to much...

With electricity making leaps and bounds, and forced induction getting better, there is little incentive to reinvent the piston pump...

-

6 hours ago, Wandering Soul said:

BeanCoAuto... conserves gas... fart in a jar.

-

11 hours ago, hiro said:

It's probably prohibitively expensive to set up shop to build something new like that. Then you need people who know how to service it. And where would you get parts for it?

Questions like that didn't stop Ford or Edison. In fact Ford was all about selling parts because he knew that's where the money was... still applies today. Parts and service... a fricken nightmare.

-

1

1

-

-

12 hours ago, CrazySkullCrusher said:

If you want to see a really innovative engine design look into OPOC (opposed piston, opposed cylinder) engines. Perfect primary and secondary balance, light weight, very few moving parts and incredibly efficient.

I saw that and immediately thought of the BMW in reverse. Yes... I think that engine is pretty sweet and I am surprised that BMW is not on that bandwagon.

-

12 hours ago, magley64 said:

There are a few challenges with implementation of an engine like this... Rotating surfaces, dynamic seals, etc... And the performance difference doesn't amount to much...With electricity making leaps and bounds, and forced induction getting better, there is little incentive to reinvent the piston pump...

Yes, electricity has huge torque advantages over conventional engines and the batteries are getting much better.

As for distances... you cannot beat gas, hands down, for now.

According to claims... this type of engine is not only much lighter, consumes less gas, much smaller, less complicated and thus more reliable, it also has more power.

But theory is doesn't amount to a hill of beans if your life is on the line. -

1 hour ago, Wandering Soul said:

I'd prefer something a little more traditional...

Hell yeah! I can dig it.

I just might go that route if this doesn't work.

I went and got me some toys and a little more know-how.

First I'll try the cheap and nasty J-B Weld to BJ the thing.

If that don't work... I'll try to braze.

J-B Weld is rated for 550F, which seems good enough as these motors run something like 250F

J-B Hi-Temp Red Silicone Gasket Maker is rated for 650F

On a side note Aluminum melts at something like 1200F, which my friend and I do for casting.

Now, if all that kludge gets FUBAR I'll try Aluminum brazing.

The one's in the attached picture is bronze... wrong stuff and another reason why I'm trying the J-B Weld first: I don't want to go back to the store and buy more stuff.

And a shout out thanks to @Qman for mentioning a regulator "Wow...a pressure regulator! My compressor already has one on it!" on the "Tire Gauge Sale On Amazon" topic. I picked one one up from Lowes which ... which I attached after blowing a valve on my new crappy grinder from Harbor Freight.

Source:-

1

1

-

-

1 hour ago, ReconRat said:

I've fixed cracked aluminum castings various ways. None lasted forever. All methods leaked again. Probably the number of heat and cool cycles just crack the patch. Even a weld. Super glue impressed me, it was just so easy to do, even if having to put more on often. Trying to fix or plug up a large crack or hole is a waste of time. But it might work for a while.

Yeah... I don't expect this to last forever... I'll use duct-tape before spending more than $500 on this engine.

If I'm going to put more than $500 into this engine... I'm going jet. -

Why hasn't a motorcycle been made with this engine, the Duke engine?

This seems to make perfect sense. -

39 minutes ago, 2talltim said:

If you really wanna

JB Weld looks like a quick and dirty solution. I wonder if I can get 5 years out of that method.

-

21 minutes ago, Wandering Soul said:

I'm going to disagree with Tim; my experience with those motors has been good, I'm on my third one in 40 years. One of them still running for a lady I know.

Is the crack all the way through? Getting oil out of it? In order to tig or brazed, it has to be cleaned and the crack stop-drilled at it's end 1/16" drill is good. Clean it with soap, water, and compressed air acetone doesn't seem to like tig/brazing. I would not use JBWeld as suggest in the video. If that stuff falls into the crankcase who knows what all it'll fuck up. Someone sells aluminum bars that a MAP gas torch will melt. Seen a Sportster primary cover fixed with one of them. Two years now and holding up good.

There's videos on youtube about the aluminum stick and MAP gas. Also on Kohler engine repairs. Find Kohler's website and download the manual for that motor (free). Also order any gaskets and pieces you need. I love my local dealer, but Kohler's site is cheaper even with shipping.

Thanks for your generous post. The crack must be all the way through because oil was all over the garage floor and bone dry. I'm hoping this is the only crack.

I'm glad you said something about acetone. I was going to use it to clean. I'll hold off on that. -

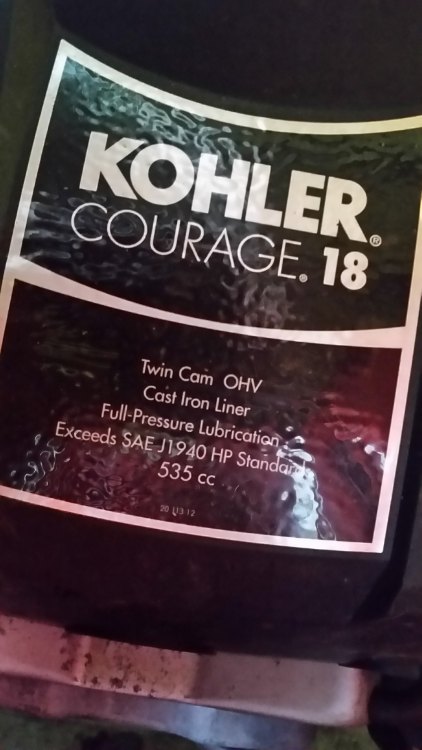

Ok... any mechanics out there? Here's the deal... this is an aluminum short block for a lawnmower... but I'm guessing that should not matter to people who like to work on motors. I found the crack and I want to fix it. The problem is ... I have never done this sort of thing before and I am not intimidated to learn and try. After all, I rebuilt the transmission on this thing and it works like a champ. People told me fixing a transmission is too difficult for a noob but I proved them wrong. Another reason for wanting to learn how to fix this thing is if I'm on the road with my bike to Alaska and get stuck in BFE I would like to be able to fix a hole or a crack so I can limp into town or keep going if the fix is good enough.

Here are the photos of the beast.

I'm looking for the right solution - so all you grease monkeys out there... here's your chance to shine and show what you know: JB Weld, Steelstick. tig welding, Alutight, brazing, ???

Your advice and instructions will be very much appreciated. -

8 hours ago, nebbish said:

I left Kent and went south. Ended up down by WV.

I was considering heading out to West Virginia over the weekend... to much work around the house.

That trip will be coming soon.

Any suggested routes and sights? -

I took the bike out for a simple ride, and the waft of estrogen laden perfume perforated the air like a wet dog destroying the couch after a bath. I mean wow! All the chick-a-dees were out and I never seen so many guys on bikes cruising on the crotch rockets. Where were they in January like I was? But who cares... it's Spring, mid 60's and NEO was in all her splendor. It was a great day to be out. Who else was out riding today?

-

Almost a bad day... I needed a break from reality for a thirty minute putt around the block. It turned out to be a SIX hour love-fest on two wheels: out Black Horse, Chagrin Falls, Mayfield by way of back roads, into Cleveland and back again. I even road through the cemetery by Little Italy and caught a video of biggest Tom turkey I've ever seen in the wild. Lucky him, KFC was no where to be found.

-

.thumb.jpg.b493a60e22cb93e8c59c7602670c8247.jpg)

Cracked Case - Oil Splattering All Over the Place

in Tech and Tips

Posted

A man's work is never done. Everything looks great.. then the muffler blew from an earlier repair. Who makes this crap!? Does anyone have a muffler?