-

Posts

1,259 -

Joined

-

Last visited

-

Days Won

193

Content Type

Profiles

Forums

Gallery

Store

Calendar

Posts posted by MSerfozo

-

-

-

-

-

1 hour ago, Pauly said:

I was referring to the wheel valve stem for Rick's amusement, but yes.. I have a brake bleeder up top.

Duh, I thought you were talking about the Brembos!

-

1

1

-

-

-

-

11 hours ago, durk said:

Not the tire. The valve stem. I don’t replace them every time I change a tire. I picked up a new stem tonight. Now I just need to find the time to replace it. Guess I didn’t describe the issue very well.

Have you ever tried the 90deg aluminum stems? Makes it a lot easier to get the air chuck on. I use silver ones on my black rims so they're easier to see when I'm rolling the bike around in poor light in the garage.

-

-

Cleaned carbs last night. 🤮

Monday evening when I was coming home, I thought I was running out of gas but realized that I didn't read the markings on my new (to me) Pingel petcock and I wasn't on reserve like I thought. Good news right? I still had some gas to get home! I fiddled with the petcock and got it onto reserve and started riding home. The bike started running really rough and the O2 was reading really lean. I stopped at a light and smelled gas and when I looked down I could see gas pouring out of the carbs on the right side. I made it home and shut the gas off and the leaking finally stopped. I am assuming that when I went to reserve with the new petcock, some crap from the bottom of the tank got sucked into the carbs and at least one had its float valve stuck open.

Bt the time I got home Monday, it was too late and I was too pissed off to think about working on the bike. When it's time to clean carbs is the only time I ever wish I had fewer than 4 cylinders!

Anyway, It's running perfectly today!

-

3

3

-

-

-

Down from 224 when I retired last August to 191 today! Got at least 10 more to go.

Switching from beer to bourbon helped a lot!

-

1

1

-

1

1

-

-

-

Pavers can be slippery, especially when wet.

-

1

1

-

-

Brake fluid today. Pretty boring so no pics. All M/Cs have new, clear, DOT4 fluid now.

-

-

Love the illustration with the 1974ish Alfa Romeo Spyder.

-

-

-

-

Cool idea! Always wondered what to do with them.

-

Admittedly, when the top end is actually on top instead of on the side like a BMW, it's a little harder to set valve clearances. But on an old-school oil-boiler naked, it's not a lot harder! And with tappet adjusters, the adjustment is easy with common hand tools.

While I had the tank off, I took the opportunity to install the Pingel petcock I had laying around.

-

1

1

-

1

1

-

1

1

-

-

-

11 hours ago, Tonik said:

Dang man, that is quality work.

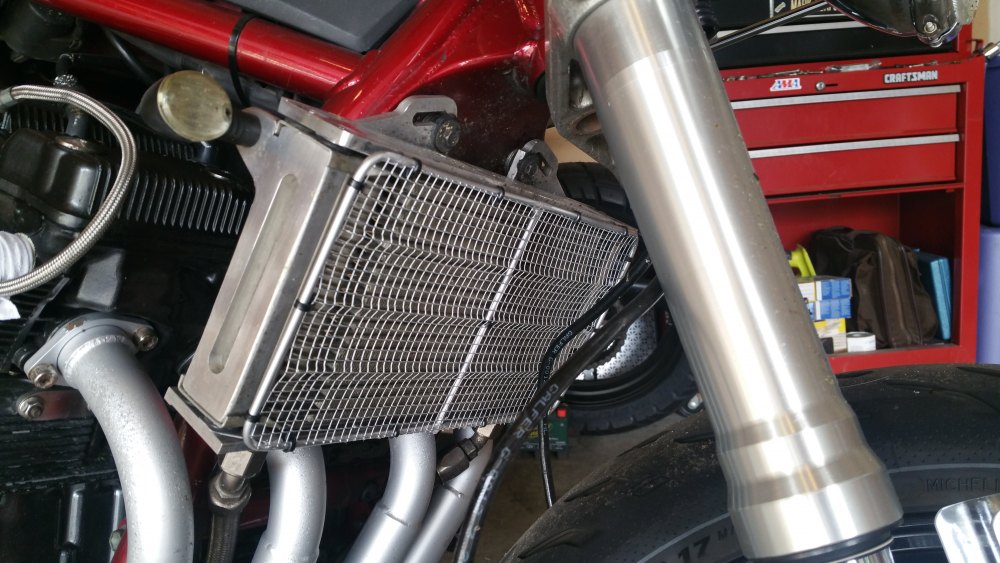

If it keeps road debris from letting the oil out of the cooler, I'll call it quality. It doesn't look that great up close, but the old one had less open space and the new motor heats the oil up more than the old one did.

-

I finally finished and installed the new oil cooler guard. It's been about a month since I started building it - I guess the cold garage has slowed progress.

I started by making a form for the frame and bending a 3/16" rod into the shape. Then I welded the frame together and tacked on tabs for the corners. I AM NOT A WELDER, I merely own a machine that can weld when in the right hands... But with enough sputtering and grinding, I can usually get two pieces of steel to become one. I tried to weld the wire screen to the frame but failed so I opted for zip ties. A quick coat of aluminum color spray paint and I called it finished.

I'm reasonably pleased with the outcome.

-

2

2

-

Funny picture thread.

in Pics and Vids

Posted