-

Posts

2,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Events

Posts posted by Dweezel

-

-

bummer.

That's a bitch!

better jump back in the sauna

better jump back in the sauna -

There's a page 2!? You need to set your page limit to 40 posts/page, unless you royally suck and still have dial up

-

The issue here (like everywhere in the automotive world) is TIRES. Period. A RWD is fine in the snow with the right tires, and the whole FWD is better is just a missconception since the added weight over the drive wheels that negates the need for specialty tires somewhat. Kinda like a tractor trailer. They're so heavy that they can literally melt the ice under the tires by sheer friction. Now a FWD is obviously not this extreme but you get the point.

Also you have to take into account the vehicle and tires mags is talkin about. A heavy older car with surprisingly a decently close 50/50 weight bias with neutral handeling. I had a 1 ton GMC ext cab long bed that I've gotten stuck in due to the crown in the road. Thing was useless in the snow, even with a 1850lb electric motor in the bed, but slightly less with the extra weight. Highway tires and sever lack of proportionate weight over the drives made it useless. I've also owned several jeeps, and a few SUV's with all-terrain and mud terrains that I rarely ever use 4wd on, the quality of the tire (I run only BFGoodrich all, or mud terrain on my trucks) makes it in nessicary. However the 4wd makes it really nice to be able to get yourself out of ditches.

In reality in the majority of driving situations RWD is superior to FWD for a variaty of reasons.

-

I wish there wern't flurries here yesterday morning

It's still only 34 degrees

It's still only 34 degrees -

Eh, their calling for freakin SNOW here tomorrow morning

If it's decent I'll be down, but 3 1/2 hrs in 35 degree weather isn't my thing. Let's hope it's atleast mid 40's tomorrow morning

-

wow, really, not too shabby at all.

-

Thats my preferred method

Gobs of TQ below 5k rpms will give you good hp numbers (muscle car method), or you can spin it to 50k rpms (Import method).

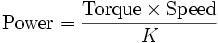

Gobs of TQ below 5k rpms will give you good hp numbers (muscle car method), or you can spin it to 50k rpms (Import method). HP=Tq*RPM/5252 There is no such thing as HP, it's a number achieved from mathematical formula. Torque, is a measurable twisting force around a center point that can be measured, nominaly in Nm or, Lbs/Ft.

-

:goaway:

Er... I mean

yeah thats it

yeah thats it -

i like www.dynotune.org stuff. ive gotten a few things off of them its good stuff

-

You must use oil that meets the specifications set in your owners manual. these are usually two letters. If you put an oil not made for the high pressures and speeds a sport bike engine can acheive you can do damage. also the oil in your bike is engine oil, transmission oil, and clutch oil. Your not riding some POS Hardley Daverson that uses 3 different types of oil where anything short of warm crisco will work.

Synthetics would actually be more suited to a Sport Bike that lives the majority of it's life at or above 4k rpms, they have higher resistance to thermal break down, and are longer lasting. Again, just be sure your getting the correct stuff for your bike.

Yes you can switch between the two, you can go from Dino juice, to Syn, and back to Dyno Juice with no worries, You can even mix them together with no problems.

-

Hell yeah it is, It's SPEC racing. Thats all. NASCAR's advancement in cars stopped with the roller cam/rocker assy. Good Bye Hill billys

"Hey look! Their making a left!!!" Please.

-

"....I'm a man of wealth and taste

I've been around for a long, long year

Stole many a man's soul and faith "

Ahhh, I love that song

-

Soooo.... I'm running Vista with all the current updates, Windows Defender, and all that jazz, I should be okay? I can get to all those sites and updated my VDB earlier today and scanned (does it automatically while I'm at work) and everything came up clean.

-

holy crap! welcome back! i was starting to worry about you mang!!!

-

there is a guy here who had a 'Bus who was running high/mid 7's, it was scary to watch because he'd go down the whole track spinning and the ass end all squirrely. bad machine, consistantly trapped 183-186 mph!!

-

-

I've got an Air cooled Porsche sitting in my garage, Hang on I'll go snap a pic..

-

I've got Gmail and I always get them shortly after their sent.

-

yeah, it hasn't been too bad. I was in pittsburgh last week... definitely better than pittsburgh!!

I'm glad to see that everyone has been out riding though, gives me a reason to want to come home.

I'm not reason enough

(okay okay, WE'RE not reason enough

)

) -

Their not bad. About the same as an S2000. They both looked

-

China is going to take over the US, not by force, or superior arms, their simply going to buy us. Thats the wonderful thing about America, everything is for sale, at this point, even the country it's self.

-

-

Holy fuck. As someone who works with the removal and disposal of LEAD BASED INDUSTRIAL PAINTS found on bridges and above ground water storage units, yes, you'd be amazed at how many above ground municipal water storage tanks have lead based paints lining the inside of them, but there's a reason you're all still alive and healthy, lead won't dissolve in water. I've had way, way more lead training than any one person could ever use in a lifetime, I've got an OH, PA, NJ, CA, NY, DE, and MD lead licence (several of which have expired, you have to re-train, and re-test yearly), it's all the same shit, oh my god, i get the point already.

That being said, lead can only be ingested one of 2 ways, through the digestive, or respiratory tract. for that to take place it must be in a dust, fine powder, vapor (buring) or other small, easily broken down form (think small dusty paint chips). If you swallowed a lead sinker, you would absorb no lead from it.

You cannot absorb lead through your skin. as ReconRat said, a kid would have to grind up, and ingested an entire motorcycle. This lady is just being a cunt and going out of her way to cause undue harm and stress to the American public because she can. She needs executed promptly for her role.

Lead is as dangerous as they say, but it's not as easy to ingest as they'll have you believe. Simply standing in a room with a box of fishing sinkers won't kill you.

-

nothing formal, lets just say anything mechanical to me is a easy as breathing is to most people. I've got an inherent knack to just be able to conceptualize and break things down. I started out laboring there, then welder, then fabricator/fitter. I had the mechanical aspect of the machine down after a few weeks, After a year or so I had the electrical system down pat from wiring them, and I didn't know what little things on the prints meant, that bothered me, so I taught myself how to read electrical blueprints. I started answering allot of the questions that people were asking, thankfully my employer appreciates me and realizes I've got some potential, I started out doing service on the equipment, then I went out with the shop foreman who used to do the training, after about 5-6 of those he quit coming and here I am. I've also done allot of the blue prints for them in the office. I took drafting in HS and used AutoCAD LT, got online and brushed up on what I couldn't remember, and did layouts for about a year (after I broke my collarbone in OCT of '07), now I'm back out in the shop doing fab work and welding thank god. I can't stand to be cramped up in an office sitting behind a desk all day, Thats why I dropped out of collage, was working on an IT degree, after about a year and a half of that I couldn't take it any more.

I also drew up and brought to light our 'wireless blasting system'. Working in Philly our biggest problem was crossed, shorted and cut wires. Every blaster, up to 6, has to have a wire from the machine, to his trigger, sometimes up to 2000' of wire, times 6 guys, at about $1.20 a foot, thats allot of money and problems. As soon as I got back to ARS from Philly, I started working on that with a top end wireless controller manufacturer, they do wireless remotes for cranes, locomotives and allot of other industrial applications. We're past the prototypes, and onto our 4th full production unit. We out source the control and encoding/decoding to them, and when they get in I wire the box and put a pigtail and quick connect plug on it so they can hook it up to any of our machines, and then just run 20' of wire from the box to the blasters control on his nozzle and your in business. only about 20' of wire per blaster, and NO tracking down wiring problems.

My father also always told me there's no such thing as you can't, only you won't. lots of truth to that.

How bout a myspace/facebook thread!!

in Pics and Vids

Posted

Ya know, I was thinking, you know what this site could REALLY use. Some sort of feature where you typed in a keyword or phrase and this complex code could sort through all the posts new and old and fine ones similar to, or including your criteria! It'd be awesome! There would be so much usefullness to that! We could call it 'FIND' or 'LOOK FOR' or 'SEARCH'!! Yeah that's it! 'SEARCH' and maybe put it on the top of EVERY page! Okay maybe I'm getting carried away here but I think it's a GREAT idea! Quick, someone PM Casper the friendly cracker and see what it would take to impliment this piece of awesomeness into his site!