-

Posts

197 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Events

Everything posted by imagineer

-

It was sold to a person in Barberton

-

Anyone in NE Ohio looking for a go-fast toy? https://akroncanton.craigslist.org/mcy/7515694684.html I've outgrown the need for speed and this one is just sitting unused.

-

I can’t decide if I want to put the $$ into my ’02 Bandit 1200, or just sell it. Although I say I enjoy this bike, I don’t use it much at all. Looking at the year-to-year mileage, I’m riding it less each year. 2017 = 575 miles 2018 = 433 miles, 2019 = 473 miles, 2020 = 288 miles, 2021 = 162 miles 2022 = 12 miles (so far) When travel via 2 wheels is an option, my fat, heavy V-twin cruiser is the ride of choice. I also have a storage space dilemma now that there’s extra equipment and a 50 year old (albeit ‘tiny’) British car parked in my workshop. Not including tires, it’s going to take about $400 to fix the immediate needs (petcock and carbs). This bike has been down for about 2 months and so far, hasn’t been a priority. I’m buried with work and other projects and probably won’t have time for another month or two to work on it. The good: Despite the 40k+ miles on it, it’s a solid motor and transmission, and when running well, is really quick. It has a Dale Walker Holeshot Stage 1 jet kit and a 5 degree advancer. It’s been converted to a solo seat with a custom made, all steel tail section. It’s got a custom-made muffler (similar to a Supertrapp) along with a spare 4:1 header. It’s also got a custom front fender, headlight and turn signals, and Renthal superbike bars. The bad: It needs a new fuel petcock. It needs another carburetor rebuild (or at least new float valves) and an oil change. I’ve been messing with velocity stacks (still have, but not using the stock airbox), but still don’t have it dialed in yet. There’s a small dent and blemish on the fuel tank and the paint on the rear cowl is chipped. The chain and rear sprocket are still usable, but I’m sure worn enough to warrant replacing. The tires aren’t bald yet but are old and should be replaced. Ok, what would you do? Invest (in everything), eventually fix it and keep it? Invest (in the minimum), eventually make it run well and sell it for more $ later this summer? Or just face reality and sell it now for what I can get for it?

-

-

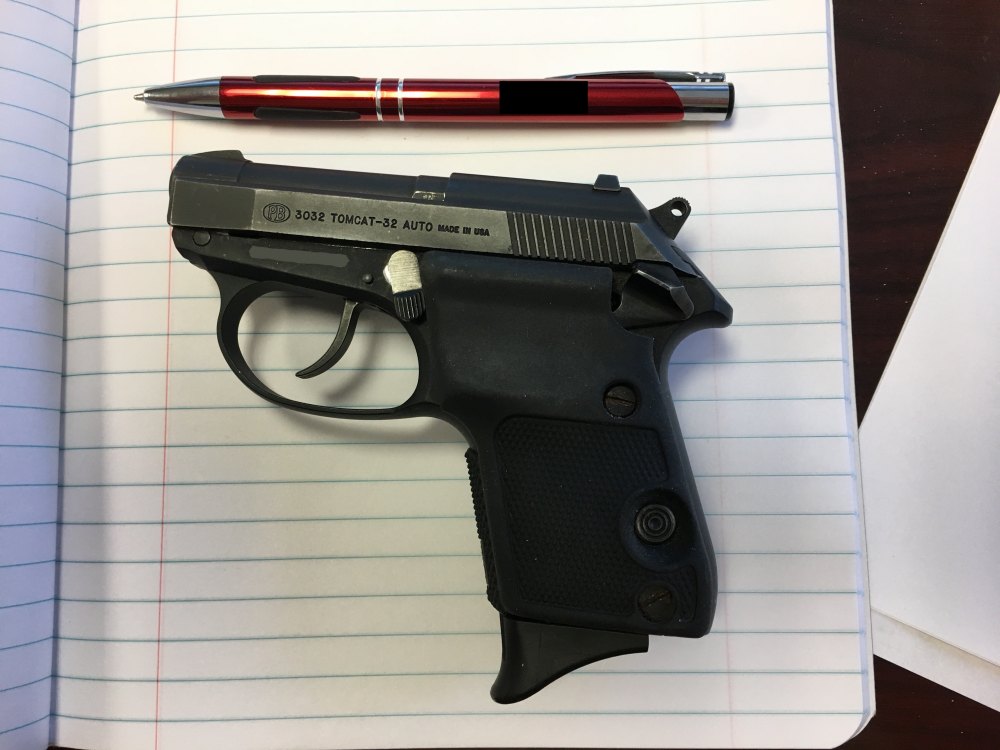

My $100 Beretta Tomcat 3032. A few weeks ago, I was approached by a co-worker, who on behalf of a “friend”, who was doing a favor for a “buddy” looking to sell some of his guns. I happened to have a C-note in my pocket and picked up this weird little gun (w/ a case, holster and 50 rounds). It’s a .32 caliber semi-auto and although you can chamber a round by racking the slide, it’s intended you push a small lever (left side, just ahead of the grip) forward and the front section of the barrel disengages and rotates upward, exposing the breach for inserting the 1st round. It shoots great as long as you grip the snot out of it. This got me thinking, what $100 (or less) handguns have you all bought?

-

Assembled this last weekend. Nothing all that special, Anderson lower receiver with a PSA 16", Nitride, Magpul kit.

-

Bought the LCP2 about a month ago ($230). Put about 50 rounds thru it at the range. So far, not very impressed. Lot's of stuck casings. I'm told it needs another 150 rounds to break in, and I probably need to stiffen the wrist. Trigger seems fine, but I'm also comparing it to a S&W Sigma .40.

-

Well, it lives . . . and isn't leaking! I'm guessing it was simply one or two stuck float valves. During the second tear down of the carbs today, I shot a bit of WD-40 in each valve body before installing the valve. The test ride went OK, but not stellar. The bike finally idles well and with a responsible amount of throttle, it runs well. Should I choose to be a bit irresponsible, at about 3/4 full, and If I gun it, the engine stumbles badly. I'm not as skilled in carburetor diagnosing as some members here, so I don't know for certain if it's running rich or lean, but I'm guessing lean. Here's why, The Holeshot Stage 1 kit had 3 different size main jets, 107.5, 110 and 112 and the instructions clearly state that for my conditions, I should install the 110's. Stupid me, I installed the 107.5 set. I just went out to the barn to confirm and yup, the 110's are still sitting in the nifty plastic case. I know what I'll be doing tomorrow.

-

I didn't take the bank of 4 carbs apart so the fuel pipes were never disconnected. Thanks for the picture. That's exactly how I assembled the shims on the needles. I just tore down the carbs again and confirmed all was assembled correctly and also confirmed the float heights. I'll be putting fuel to it again in a few minutes, but wanted to check the web first to see what folks think the problem is.

-

Well, I tried getting the bandit started, the carbs leaked fuel all over the place and I can't figure out what I did wrong (and I still haven't solved the problem with the throttle not closing on it's own). For gas, I'm not using the bikes fuel tank, but was using an auxiliary fuel bottle (think I.V bottle). I didn't measure the float height while I had the bowls off. I figured it wasn't leaking before, so the float levels should still be OK. Could that be the root cause? As part of the Holeshot Stage 1 kit, after swapping out the jets, I was instructed disassemble the tops of the carburetors and to slide little shims (5 of them) over the pointy end of each needle valve and then reinstall into the diaphragms. Anyone done this before? Does the picture below seem correct? Also, probably at some point while reinstalling the cabs, a rubber t-fitting the bridges the top/rear side of carbs 3 & 4 got knocked off. When the carbs were leaking gas, it seemed as if gas was pouring out at this location too. In the picture below, the T-fitting is installed, but it fits somewhat loose. I can't imagine this fitting is supposed to be fuel tight? There are no similar T-fittings between any of the other carburetors. And this 1 T-fitting is connected to a clear plastic tube that goes nowhere Any advice?

-

I didn’t sell it, rather I (stupidly) traded it straight up for a ’97 Jeep TJ, 4cyl, 5spd. Although I’ve been enjoying the heck out of the Jeep, I missed having, and tinkering with the Bandit. About a year after trading the bike away, I was searching Craigslist for another Bandit, or other inline 4 sport bike, to play around with. I expanded my search to cover Cleveland and what do I see…yup, my old bike up for sale or trade. The seller even used the same write up I originally used. Long story shortened, I reached out to the seller, offered a crazy low-ball number…and she accepted (probably helped that she just bought a house and needed cash). So, for really short $$, I have a fun little Jeep and the Bandit. When I picked it up in Cleveland, there were only 2 more miles on it than when I traded it away. Turns out the person I traded it to, had never before ridden a sport bike. Her 1st ride, she did one inadvertent wheelie, skidded to a stop and then dropped it. After that, the bike sat untouched in her apartment parking lot for almost 11 months. There’s a bit of rust here and there and the rattle can paint on the rear cowl cracked, but after getting it home and dropping in a fresh battery, it started just fine. Ran like $hit, probably because the carbs were a bit gummed up. Last weekend I cleaned out the carbs, and while apart, I put in a Dale Walker Holeshot Stage 1 Jet kit. I also put in 5 degree timing advancer. I ran out of time to get it started again and balance the carbs, so that will probably have to wait a week or two until I have an open afternoon. In the meantime, I’m hoping to solve the throttle cable problem. Sounds like the cables are simply too tight.

-

I just finished installing new carb jets on my '02 Bandit 1200 and now the throttle doesn't close on it's own. I didn't kink or over stress the cables when removing/reinstalling the carbs. I know the problem is not with any of the moving parts on the carb array as it snaps shut smoothly. The problem presents when the cables are installed. Are there any tricks to try out before replacing the cables? Maybe adding an extra return spring?

-

Found a used Ibanez A/E. thinline on CL, going to look it over tomorrow...

-

Question for the guitar players out there... I’m finally pulling the trigger on my last bucket list item…learning to play guitar. I’ve tried self-teaching several times over the years and failed/quit for one reason or another. Along with having zero musical ability or experience, I’m also fatally left handed, so all the effort trying to learn with a right handed instrument was a total waste. So, moving forward I just found out, there’s a well-respected (and reasonably priced) guitar instructor about 10 minutes equally from my house and office, and he’s available for hour long lessons mid-day during the week, i.e. lessons during lunch time. This kills two birds; it doesn’t take evening or weekend time away from the wife/family/projects and also forces me to get out the office for a bit and break up my normal 10-12 hour work day. So, it’s time to buy an axe…Obviously, I’m not going to run out and spend $1500 on a top of the line professional quality instrument but I’m also hoping to do better than a $100 Daisy Rock from Walmart. In reviewing the readily available options, I’m leaning toward an Ibanez acoustic/electric thin-line, cut away style (it’s in the sweet spot of the budget and it looks snazzy). https://www.amazon.com/Ibanez-AEG10LII-Cutaway-Acoustic-Electric-Guitar/dp/B00ESK5YX6/ref=s9_simh_gw_g267_i1_r?_encoding=UTF8&fpl=fresh&pf_rd_m=ATVPDKIKX0DER&pf_rd_s=&pf_rd_r=7DC1ST9ZSVDYGY6DA4V9&pf_rd_t=36701&pf_rd_p=a6aaf593-1ba4-4f4e-bdcc-0febe090b8ed&pf_rd_i=desktop Is there any benefit, or detriment to going with a thin-line guitar versus a full body?

-

I ended up buying a CarbTune 2. Found a new unopened one on Ebay for $60 w/ free shipping (it also included a goofy looking long screwdriver)

-

Along with my recently re-acquired Bandit 1200, I've got another other inline four cylinder bike projects in my work shop. Both will be getting carburetor tear-down and cleaning; and will eventually need the carbs balanced, so I'm looking at buying a sync/balancer tool. I'm finding carb tool options, some that offer dial gauges, and other that offer graduated columns of mercury (or colored water). I'd like to hear from those that own a carb sync/balancer tool. What type do you use and do you have any recommendations for what to look for when shopping for one.

-

Look what returned !! Last January, in a moment of foolishness, I traded away this bike for a Jeep Wrangler. Although I enjoy the heck out of the Jeep, I've continuously regretted letting go of the bike. To appease my anguish, I've been shopping Craigslist for another Bandit to work on. A week or so ago, what do I see, but an ad looking to sell my old bike (or trade it for a Jeep). I reached out to the ad, turns out it was the same woman I traded with last January. She said it was way too much bike for her, and too tall as well. In the 11 months, she put less than 100 miles on it. Although she was asking $2300, I offered about half . . . and she accepted! So, I still have the Jeep, and my bike; and I'm out only $1200.

-

Would you buy a cheap P.O.S. pickup, or a single axle 1500lb - 2000lb capacity trailer?Here's the deal. Maybe 6 times/year, I need to pick up or deliver something that's too large/heavy to fit in my car. On these occasions, as much as it pains me to do so, I'll borrow my father-in-law's pick up (90's S-10, 2wd). Most of the time, when needing a truck, I'm trying to move a motorcycle, or retrieve plywood, drywall, gravel, mulch, etc.Despite our constantly taking care of my in-laws, their needs, house and grounds; lately my father-in-law has become an a$$hole about loaning out his beloved truck; and combined that the truck is a piece of crap, makes me really reluctant to ask again.Since what ever I end up getting will probably sit outside for months untouched, I'm either going to buy a cheap, POS pickup or a new kit trailer. I'm not too keen on having another vehicle to maintain, but I know nothing about light trailer ownership and maintenance.I drive either an Outback wagon or a Jeep Wrangler and both have class 3 trailer hitches. So, you are me, and have a $800 budget, what would you get, a truck or trailer?

-

I don;t know if this qualifies as funny, but one of our temp services was concerned about the high heat earlier this week and sent over an ice tub with bottles of water for our employees...

-

FWIW, the problem is solved... An Amish employee here at my plant has a side business building strip built canoes and kayaks. Just about everyday, this poor soul wreaks of resin. I shared my tale of woe with him, and his suggestion was simply, "sand it out". As he suggested, I started with 120 grit and lightly sanded all the sticky surfaces. The paper gummed up fairly quickly, but after 2 pieces, the entire surface of the resin coated duct was sanded and no longer sticky. Again, following his suggestion, I did all the needed sanding to smooth down edges and develop a consistent white-ish surface, after which I cleaned it well using a small amount of acetone on a rag. Next I mixed a small batch of resin, using 1.5x the recommended hardener. Working quickly, I painted another coating of just resin on the sanded surfaces. He said to keep painting on layers until the resin starts to thicken and at that point, stop.I checked the project this morning and the fresh layer of resin was only a little tacky. It will sit in my 90+ degree workshop until mid day when I'll move it out into the sun.

-

A little background…I while back, I cut an opening in the batwing fairing on my motorcycle and added a NACA style duct (https://www.pegasusautoracing.com/pr...p?Product=3627) to try and balance off the pressure differential behind the fairing, all in an attempt to reduce helmet buffeting. I wasn’t happy with the results and recently 3-D printed a different design duct and over the weekend, removed the purchased duct and installed my design.Not necessary information…The batwing fairing (Memphis Shades) is made from Lucite and the duct is 3-D printed using PLA (polylactic acid). I used 2 part epoxy to first bond the duct to the fairing, and then using fiberglas and resin, completed the attachment. Here’s the start of the question… The resin set up fine and hardened as it was supposed to. However (after 26 hours), the very top layer of the surface is still very wet and sticky. I’m fairly certain it’s not a result of a bad resin/hardener ratio because the base and excess set up great. I’m also certain that ambient temperature isn’t a factor because it’s been in the 90’s for a week now. I’ve read that this is a common problem brought on by the coating of resin not being thick enough to generate its own heat for the needed chemical reaction. In these situations, folks can either wait it out, sometimes 2-3 weeks, for the resin to finally harden, or they can “dust” it with a dry filler material. The dry filler will absorb into the wet resin, building up a thick enough layer to be sanded & finished. Being the impatient sort, I’d rather go with the filler approach.Almost to the question… The, recommended dry filler materials are talc, cured bondo powder and aluminum powder. Whereas I have talcum powder available, I don’t have any cured bondo to grind down. I do, on the other hand, have more ultra fine aluminum powder than you can imagine (a product used where I work).Finally the question…Has anyone out there added aluminum powder as filler to epoxy or fiberglass resin? If so, did it affect the cure time and was it difficult to shape and sand after curing?

-

This particular project died before I could get it started. The seller wouldn't budge on price even though he was $400 over KBB. Factoring the extra $$, it wasn't worth it. I'll keep my eyes open for another car or truck to make my victim...

-

I need another project like I need a hole in my head, but … There’s a well-used, late nineties Chevy 1500 W/T 2WD pick-up for sale not too far from my house. It’s got the 4.3L V6 and a 5 speed. It’s got a few mechanical issues (but nothing that would prevent it from being driven home) and will require a fair quantity of rust repair patch panels. I’ll bet I can score it for under $600. Here’s where it gets interesting… Where I work, we had a project that called for some airbags (yes, the exact type that rodders use on cars & trucks). We ended up not using these and they’ve been sitting in boxes for a few years. I can have them (5 airbags) for free. So, should I get the truck and in what little spare time I have, convert it to 4 link, C-notch the rear frame and bag it, or forego the whole idea wait for something shiny to distract me?

-

Nah, I may have moved fah, fah away, but ahm still a fahkin Mass-hole retahd and a wicked smaht-ass.