-

Posts

584 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Events

Everything posted by vonrottes

-

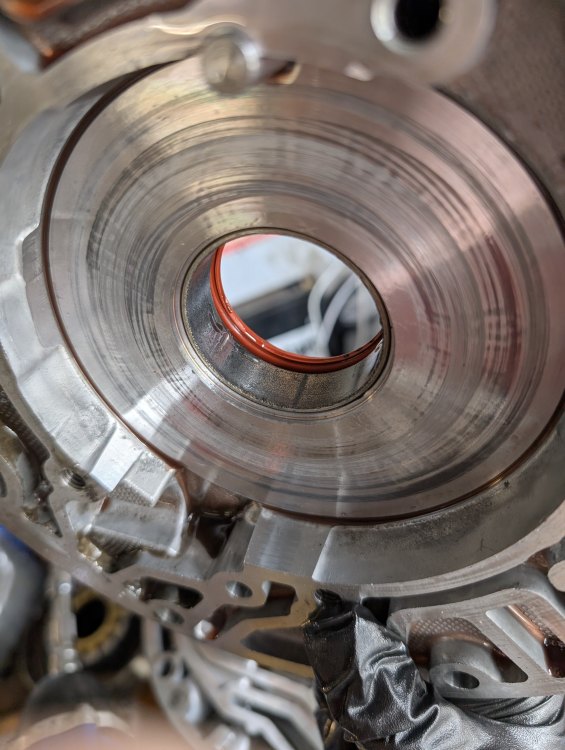

Well that was a nightmare. Went through the transmission TWICE. Replaced everything inside except the shafts and drums and it was STILL dumping glitter in the pan. Got sick of having to drive a Chevy Cruze so I picked up a junkyard 4Lslippe out of a 2002 Silverado, been running it for 2 weeks now without any issues. All I did to it was swap over my valve body, bell housing, servo, and put in a sonnax boost valve. Going to setup a camera and do a tear down video of the transmission so maybe someone smarter than me can point out where I screwed up. While I was poking around the junkyard with a friend looking for a transmission I accidentally picked up a LQ4 out of a 05 Yukon Denali and a set of 799 heads off a NNBS 5.3 It all needs a good clean, engine doesn't look like any bearings are hurt but the pickup tube Oring was rock hard and cracked when I pulled the pan after getting it home, turns over freely, makes good compression with leaky valves, cylinders are all glazed but overall I think it'll be a great engine for a 400whp goal. Going to try my hand at porting the 799 heads, only got them for the 64cc chambers to get the compression up to 10.4:1 without changing the pistons or milling the heads down, also been reading on porting the BBK intake, has a lot of potential. For the engine build, it's going to be pretty much the exact same setup I had with the L76 in the G8. So mainly just a summit 8715 cam, BTR springs, morel lifters, and then I'll also freshen up the engine new bearings, oil pump, timing set, new seals, hone the cylinders, new rings.. Again truck is doing great with the junkyard trans. 2 weeks of commuting, one trip to Chillicothe and back and one trip to prairie oaks to kayak. Chillicothe trip trans got up to about 160-170 by the time I pulled into the garage, this was with no air scoop, after reinstalling the "scoop" I made out of the fuel tank skid tray? The trip to prairie oaks and back saw a hard stop at 132°. Knowing the scoop functions as intended, I need to get a sheet of stainless and weld up a proper scoop similar to how the aftermarket heat exchangers are setup for the sy/ty

-

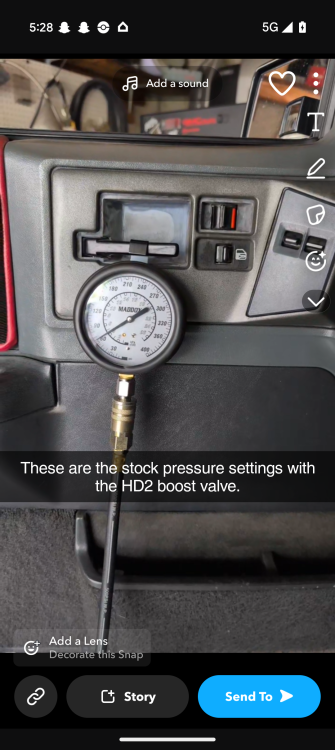

Friday night on my way home from work the transmission started shuttering and making a cavitation noise on acceleration in 1,2 and 3. checked the fluid at 150F it looked just a touch on the high side, not enough to cause issues I don't think and found a bunch more glitter, this could be the new bushings or could be a some left over from the electronics, might have missed. Soooo, hooked a pressure gauge up to the transmission. it's only running 65psi line pressure in park, neutral, OD, D, and 2 positions. reverse is 95psi. revving the engine sees nearly no change when revving, holding the brakes and revving to around 2500rpm sees a quick jump to 95psi. using HPT scanner, I can command higher line pressure 900-980mv are within the GM spec under 900mv sees quite a bit more pressure, which I would expect to see with the boost valve. I just, don't know why it's commanding 1.07v for pressure, force current motor voltage is all stock.. gonna go ahead and drops the pan tomorrow, I do believe I may have put a spring or two in the wrong spots in the valve body, so that might be an issue and addressing the glitter I'll check for evidence of bushing failure. maybe I can get away with just fixing the springs in the valve body, without pulling the trans out of the truck.. if I find evidence of fresh glitter, I'll pull the whole thing, replace all the bushings again and sand all the shafts again like Sonnax recommends, and while it's apart I'll also replace the thrust bearings, they didn't FEEL bad when I had it all apart and I soaked them in fresh fluid with the clutches, also going to do the sonnax pump spring.. So back up on Jack stands... Thinking it's a real Syclone or something 🤣

-

Well so far seems the transmission if fine! I didn't see anything online about doing it but, I pulled the fuel pump fuse and cranked the truck over to prime the transmission pump and cooler before I started it, sucked up 8 quarts REAL quick. Taking a total (including what I dumped in the TC) of 12.5-13 quarts. New transmission mount is way overkill. Attached some beefy scrap angle iron to the core support with stainless rivnuts and put some rivnuts in the angle iron to mount the cooler directly to it. Forgot to take a picture behind the bumper, but here's what it looks like from the front. Next up I'll work on getting a scoop for it to mimic the aftermarket ones for the typhoon and Syclone heat exchanger, since it's mounted in roughly the same spot. Took a pretty rowdy spina round the neighborhood after running it through all the gears on jackstands and saw 132°F so I think it's going to need more airflow or a bigger cooler (this is the B&M 20,000btu cooler) The ONLY issues are... The 1-2 shift is a little soft for my liking but, I'm sure that's because I went from the trans go 1-2 spring setup to the sonnax OEM replacement spring and the converter probably doesn't help that. 2-3 and 3-4 felt very solid on the jackstands, only hit the 2-3 once in the neighborhood and I still have some pretty aggressive torque management on that one. The second issue is... I messed up the shifter cable yesterday trying to adjust it... Now I can only hit reverse and neutral from park. Only thing it hits from drive it park, ordered a new one since there is only one place in Florida to get the stupid extra long C4 shift cable for these trucks 🤣 And of course I had to check and make sure the rattles and clunks were gone on hard acceleration https://youtu.be/std3CxQgZS4?si=VfYN3kPvYn_wiiUK

-

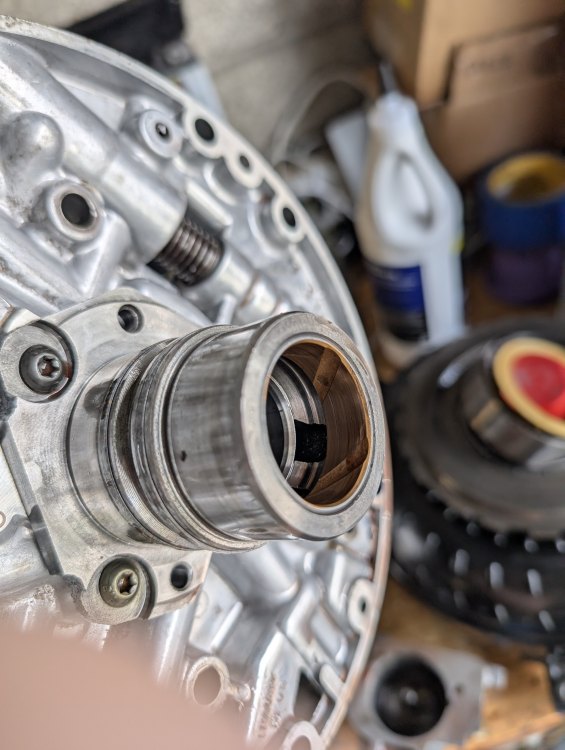

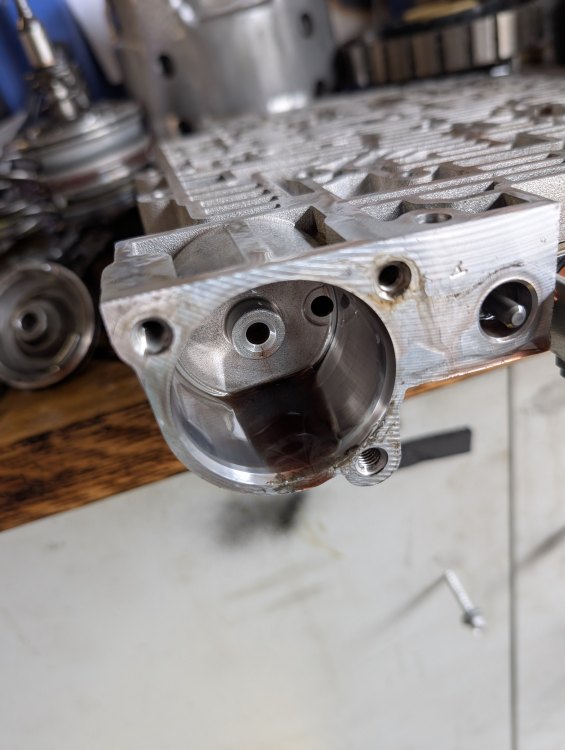

Got the rear planetary rebuilt with the Sonnax kit on Friday morning, spent most of the day waiting on last minute tool orders to show up so I could start rebuilding the rest of the transmission. then struggled with the springs in the valve body since I just kinda....plopped everything out for cleaning, the manual and rebuild guide definitely showed different parts and the trans go instructions helped but most of the color on the springs had worn off....So HOPEFULLY I got that all put back together properly, Then I struggled with the thrust bearing on the rear planetary the rebuild guide looked like it was showing a smaller diameter bearing so I was using on that the rear planetary spline stub was riding on, and that prevented the low/reverse snap ring from going in.... I pulled it all apart SEVERAL times, measured everything several times, checked it against the stock clutch pack and then finally realized I was using the wrong bearing..... After that though it all went together rather quickly and without much fuss. I got rid of the "truck" yoke oil seal? since the S10 yoke is sealed it was just and extra part. ended up using no shims on the servo, test fit with one had the band locked up tight and even with no shim it's still pretty tight to turn the output shaft. I did test fit the new converter and spin the pump over, felt smooth but did have some resistance on the input shaft. just gonna chalk the resistance up to the high energy frictions, they were really grippy during installation after soaking for 2-3 days in DEX VI, turns in reverse with very little resistance like before, and I did check the movement on all the apply pistons during assembly and they all actuated properly and no leaks. Waiting on a sonnax 1-2 accumulator spring since I forgot the trans go springs don't work with the pinless pistons.. but its all ready to go in the truck tomorrow and HOPEFULLY it works....

-

The only thing my cars go to the shop for is new tires and alignments. with an ATSG manual, and YouTube I think I got this.... Maybe 🤣

-

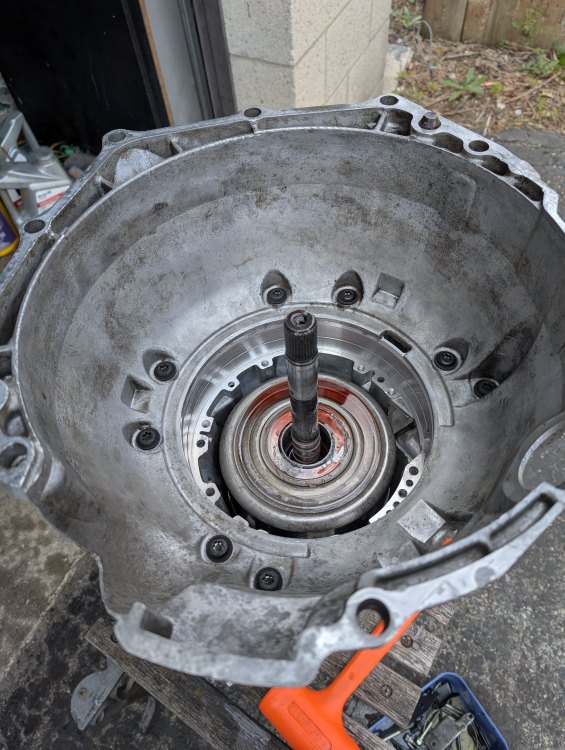

Went ahead and ordered a new converter because I was convinced that was the issue.... Hard launch might have worked the inside somehow. And what a difference between the stock 12" and the new 10" But as soon as I pulled the pan I was unpleasantly surprised with this mess. A whole lot of bushing material in the fluid....like.... A WHOLE LOT so I went ahead and with no previous experience I ripped the transmission apart. Initial inspection hard parks all looked good except the rear planetary, clutches are toast and every bushing is trashed. Ordered an overhaul kit, all three painless accumulators and a rear planetary rebuild kit. I really have no idea how the transmission was functioning properly outside of just noise and vibration. With the way the clutches look I would have expected this thing to be slip city. But then again I've only ever worked on dirtbike clutches before this 🤣

-

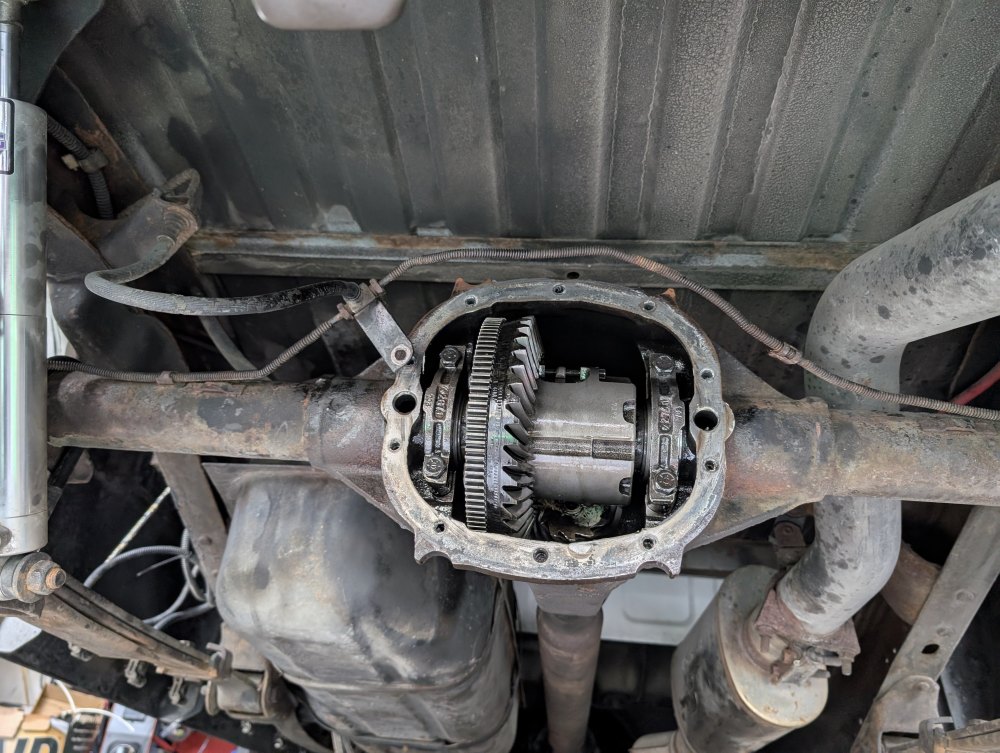

So I did end up tearing apart the rearend after changing the u joints didn't fix anything. pulling the drain plug didn't look very good... Mmmm 75w90 flavored ferrofluid.. put after I pulled the cover the differential it self looked good, but once I pulled the C-clips and pulled the axles out... oof. I'm assuming the massive amount of "tilt" the bearings had in the cage was allowing them to ride on the edges creating the uneven wear. these didn't look too great either, but some 1500 grit sand paper cleaned them up really well, aftermarket axles are definitely on the to buy list, along with new 3.73 gears after pulling the axles I went ahead and dropped the diff, and oh jeez... whoever that guy was that installed the torsen had no idea what he was doing, way too much preload (just reused stock shims) and for some reason only the driver side bearing cap was tight... passenger side was almost finger tight.... and the bearings looked AWFUL. Had to hunt down a shim kit because apparently no one keeps those in stock? Jegs had them at the warehouse, but I didn't have time to get up there on saturday after I called... Autozone hub on broad SAID they had 2 in stock, and after waiting in line for like 30 minutes.... they said "we can't find them" eventually ended up at the Autozone on East Main right down the street from the old Jegs building. which THANKFULLY had 1 set in stock overpaying of parts is my favorite thing to do. AND I STILL HAD TO WORK ON IT ON SUNDAY because SOMEONE forgot to press the bearings ALL THE WAY on... had to pull the cover, check the bearings, and reshim it on sunday...didn't take all that long to do, just annoying. And after all that.... STILL MAKING A NOISE... or well it was on Monday on my way to work, today (wednesday) doesnt seem to be making any more noise than usual, but I am suspicious of the torque converter, about a week before the rattle started it was making a louder than normal knocking sound in neutral...which the transmission of torque converter has ALWAYS made, confirmed that in 2019 when I ran the engine without the torque converter unbolted. Transmission still shifts fine, all the gears work, doesn't flare, just always has what kinda sounds like rod knock. Torque converter was replaced in 2019 with a "good" used one from a friend....but he did blow up that 4l60e. Tuesday I turned the engine over 360* from the flexplate checking for cracks or loose bolts and saw nothing obvious, and since it is accompanied by a vibration I checked the misfire count/history and both were zero on all cylinders if anyone thinks they might be able to help pinpoint the noise I got a pretty good clip of it monday night on my way home from work. audio was boosted a little to make it a little more pronounced, starts around 0:02-0:03

-

Didn't take pictures of my work, so did I really even do it? But what an absolute pita 💀 Went to jegs and picked up a valve holder/air hose thingy on Saturday, was supposed to take a ¼" NPT fitting, fitting was 5/16 compression thread... So ordered one with air fitting from Amazon, the hex on the spark plug fitting with that hose was to big to fit in the recesses on LS heads, so I had to grind down the fitting to clear.... Tried to use the cheap universal "pry bar" valve compressor and it ended up sending two valve keepers on an express one way flight to the abyss. Tried to get a hand full of replacements from the local autozone and they were useless (the hub store closest to me on West broad specifically is useless not the valve keepers) so I ended up having to go BACK to jegs and get a full set of comp keepers, and picked up the expensive bolt on valve spring compressor (because I forgot the one I already had was for LS3 style heads AND DONT FIT THE LS1 STYLE 😂) Old seals were definitely crusty with lots of sludge around the valve stem and guide under the seal. Truck is back together and seems to be running maybe a little better, wideband looks a LOT more consistent, but I haven't plugged the laptop in yet. U joints are in, originals were pretty chewed up but not loose so I think that was some vibration and noise... But the crusty bearings sound is still there on left turns, might be wheel bearings so I ordered those today. Could also just be the diff, supposedly the F body Zexel torsen make a "rusty screw" sound.... Just because 🤷♂️ idk it feels smooth when I rotate the wheels in park, and when I hold the wheels letting it idle in gear on Jack stands.. probably should have replaced the the bearing when I installed the rear brakes but they looked fine when I had the axles out.

-

Remember kids don't daily drive your projects 😂 After attempting a 1/4 mile pull the other day, the truck developed some odd noise that made me let off it before I even hit 60mph. thought it was the transmission, then I thought it was the differential or possibly the original 33 year old u joints.... after reviewing the under truck video I took trying to kind the noise, I THINK the rear strap for the fuel tank has come loose.... which would definitely cause some unsettling noises at speed.. So this weekend I'm still replacing u joints, I know they are loose but they don't seem sloppy yet, but preventative maintenance right? especially considering I'm planning on taking it down the track at least a few times in may. Also going to tackle the valve stem seals, occasionally a big ole cloud of smoke on start up. don't think it's a ring issue. valve stem seals are only 10 years old, when I had to swap the 862 heads from the 4.8 onto the new 5.3 since the 706 heads had cracks in the head bolt recesses. I deep cleaned the heads, lapped the valves and replaced valve stem seals... maybe I did it wrong, or maybe they were just crappy seals. hopefully the valves don't leak much because I don't want to pull the heads to fix the valves unless I'm doing a cam swap 😂

-

-

Oh man, there is a bunch of small things since April. Got the "new" valve covers and coil brackets installed, along with a catch can Switched all the lights over to LED with some slightly sketchy H4 projectors and even did the interior lights finally. Got the rear brakes installed and also powder coated the diff cover and battery tray while it was all apart. for smaller simpler stuff... installed power studs on the tank because I'm sick of melting the racetronix bulkheads. Primitively did the trunnion upgrade since I had a spare set of rockers, got those put in last monday. FINALLY threw in a set of 2" blocks with JTR setback plates, also did a quick buff/seal to get the paint cleaned up a little and got compliments how clean the truck looked this year! And some pictures from the trip! First stop in PA, noticed the rear looked like it was squatting pretty bad because I was also delivering a GM 8.5 to carlisle for someone. only hit the bump stops on the expansion joints on the bridges, in hindsight I probably should have turned the compression on the shocks up a click or two... second stop was in MD at the welcome center, absolutely beautiful area! And sad sunday everyone packing up I was just getting some last photos since it rained off and on most of the day on saturday

-

Featuring sportmachines and S10 Nation. I finally got to see, photograph and touch the LSR Syclone! Bonus I got to see the pikes peak truck! https://drive.google.com/drive/folders/12Oxd60IXfmwxI6XV2zpH8M2UBlCr-gA3 Photos here are original 36mp minimally compressed jpgs and the pngs that uploaded at 16bit 36mp for all the pixel porn 🤣 First time shooting with a new to me Nikkor 50mm f2 lens. And here's this from the hotel parking lot just because... Sonoma GT party .

-

Wasn't today... But Thursday I washed my bike and got it started for the first time since 2018. New battery and drained the old fuel and.... just had to make sure it still worked after letting it warm up. still needs new tires, brakes, oil change and new plugs and it should be ready to go.

-

I just feel like a dumbass, checked the ignition fuse and the starter fuse... didn't even think the accessory fuse would stop it from starting 😂

-

Nevermind, ask a stupid question before I checked the fuses.... was just the ACC fuse.

-

Trying to get my bike back up and running this year after sitting in my garage since 2018... when I turn the ignition on the running lights come on and the turn signals and horn work but the neutral light doesn't come on and the starter button does nothing (kick stand up/down, clutch in/out, kill switch on/off, 1st and neutral), jumped the starter relay and it spins over no issue but no spark, so I'm assuming the ignition isn't getting power? it's got a newer 1600 engine swap, and an aftermarket dash/ignition switch. My dad gave me this bike in 2014 and the most I've ever done is change the oil, never had to actually work on it.... I know vintage dirt bikes and LS engines.

-

Little things.... Got the rear calipers and a spare set of valve covers powder coated, so I can start making it look pretty, have some metallic grey I'm thinking about doing the coil brackets in. Soon as I have time to take the truck apart I'll get the front calipers done in the same red and make some silver reflective vinyls for them... As well as powder coating the front and rear caliper adapter brackets..

-

Out here looking extra smol next to an obs 3500 crew cab 🫠 Recently the belt has started to slip REAL bad when it's wet, definitely not enough wrap around the crank pulley (between like 5 and 7 maybe 8 ) with the AC bracket and I think the belt is slightly too long as well. Getting real close to buying an SS so I can park this thing again and start repairing and upgrading

-

Week off work has led me to finally tint the windows. 35% 3m ceramic... It's not great but idk not awful for my first time.. stuff is a lot less forgiving than 3m Scotchgard film 😅 Need to swap out the back glass, bronze for clear and tint it as well. Will probably switch to Llumar film since it's significantly cheaper for a 10' roll. Other than that I got a broke ass sand blasting and powder coating setup in the garage so get ready for all the custom coated parts like this spare 0411 I used as a test piece And I hauled off a 300lb load of scrap metal from my garage, and subsequently got to weigh the truck 3440 with half a tank of gas and me in it, she a lil piggy 🐖

-

Trying to work on cars and still have time on the weekend to do stuff sucks... thats why the leaking heater core has been temporarily bypassed. But the tune has been fixed and it feels like it's running SIGNIFICANTLY better than before, though I screwed up and the original file from the yukon PCM got lost due to the flash drive I kept all my tunes on just....died. so it's stuck in MAF enhanced RTT. Not a big deal since I'm not planning on keep the gen 3 stuff much longer, Valley knock sensor are the bane of my existence. But other than that I've not really had any motivation to do any work to it so have a picture I took at the park...

-

Oh mannnn late notice posting this one. https://www.facebook.com/MotorViceShow/ I try to go every year just becasue 90's shitbox but it's a lot of fun very 90's cringe, at Performance Auto Spa 3-7pm

-

She made it back from Carlisle without any issues....other than the ac freezing up on the highway and blowing fog when it started raining 😂 think it's still just slightly low Only issue on the way there Thursday morning was the cheapest reman alternator they had at O'Reilly's decided it couldn't do anymore than 12v with nothing but the radio on, so I threw in a NEW duralast gold Friday evening in the hotel parking lot, now holds 14v with EVERYTHING on.

-

Finishing up on my Carlisle prep... Changed the oil and spark plugs (#7 looked a little sus and #2 the retainer was broken in the boot) Scrubbed the body for a good hour, and spent a little time on the wheels cleaning them up with the special sauce and rubbed a little protectant on the tires. Two applications of All wheel cleaner brought the wheels and calipers back to what I would call acceptable.. Still want to recoat the calipers, and the wheels I'd like to strip and recoat since they have a few scratches down to the aluminum. Just need to clean up the interior... Shampoo the floor mats, vacuum the carpet and seats, wipe down the plastics, and clean the glass . Then it will be ready for the road trip Thursday morning.

-

New tires are on, chalked the tires and running 30psi in the front and 28 in the rear. ride is slightly stiffer, as expected with a lower profile tire, need to rebuild or replace the front shocks since winter destroyed them and the adjusters are locked up.. Also got a set of GMC center caps for a terrain so no mismatched logos. Probably not going to do much more until next spring, after I get my final raise at work money will no longer be an issue and I can afford a new daily and investing money in the truck. Future plans for upgrades are a Gen 4 6.0 or 6.2 and a 6l80, don't really care if I get an aluminum or iron block, just want something with rec port heads to keep parts interchangeability with my next car.. Switching to Corvette high mount alt accessory drive to clean up the front of the engine and also buy some clearance for a new radiator and bigger alternator. looking at ditching the ICT AC bracket and going cast Holley set up. Will also fix the crooked hood since the 105amp alternator is just barely touching the hood bracing with the truck bracket. Brembo calipers for the rear, already have the calipers in my garage, just need the backets and rotors. And once I get the engine and everything else sorted..... going full Restoration on the body, got some rust that needs to be fixed and paint needs to be redone, the epoxy primer my dad used is just too damn thick and its chipping like crazy.

-

Any car guys still hanging out? Looking for a GM 4T65E tyranny expert

vonrottes replied to mello dude's topic in Passing Lane

It's really not that hard to do, follow the instructions closely, keep track of everything and take your time. All of what you are doing is in the valve body, so you won't be working under the truck except to remove the valve body itself. Realistically it can be done in an afternoon after work, or if you want to take your time a Saturday. Now if you are going into the pump and stuff to install the FULL kit that is a lot more involved and does require removing the transmission.

.thumb.jpg.93c7e9d79dba4a491b7fedfd3901c3ab.jpg)

.thumb.jpg.dc75a5cee8ec8819d014379f146e7562.jpg)

.thumb.jpg.932a33892244b860e638e9ddebf71326.jpg)

.thumb.jpg.5fb142992024a55f0f79bad4f61a06c1.jpg)

.thumb.jpg.27837be6fb4ece62b9d943ff2c644dfe.jpg)