-

Posts

1,723 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Events

Everything posted by jarvismb

-

I'm going to use a solidworks plug-in to write the tooling paths. I'm learning as I go, so I'll let you know more as soon as I do. I'm an electrical engineer, but I had some time, so I knew nothing about modeling. I just spent a week teaching myself solidworks because we have it at work. Now I make all of my pcb enclosures if they need to be custom, and a bunch of models for fun. It was a useful thing to learn, so I gave it a shot. Since I'm not formally educated on this, you don't want me working on anything you really need done professionally. I'm not any good at this, it's just that the physics and structure of a suppressor are so simple that it makes it look like I know more than I do. I bet there are people on this site that could destroy me in this stuff.

-

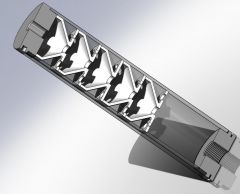

This is bored for 223/556, and is currently modeled/spec'd for a common AR15 threaded barrel. I've read about that first round pop being an issue with blast chamber designed chambers, and I have no desire to go into active oxygen displacement, so for me it was a design choice between first round pop and general baffle longevity. Just a design choice like any other. I realize this is by no means the ultimate suppressor with bleeding edge tech, it's just a design that would be effective and importantly for me, much more feasible to build with accessible tools. I've looked up normal tolerances with CNC lathing, so the design is spec'd to allow minimum wall spacing within machining tolerance, and with tight wall fittment along with the annular ledge cut into the blast chamber, the k-baffles should be concentric and aligned to within +/-0.005 just by design. I was going to play around with adding a conical crown to the entry bore of each baffle to give it a longer life, maybe I'll render and assemble one like that to see how it plays out. If I do it right, I should be able to insert either kind of baffle without any effect on the fitment of the assembly. Let me see what I can come up with, but in the mean time, so you think the blast chamber is too big to 223?

-

Perfect, thanks guys (and obviously flounder). I did a lot of reading and it's just like you said, I just want to see if I can do it. The results will be nice to shoot with, obviously, but it's as much an engineering challenge as anything else. There are tons of different ways to do them, but I opted for a modular k-baffle system since it would be easy to make with a CNC lathe. I also really like the fact that k-baffles are self-spacing and therefore do not require alternating rings and spacers. Also I can easily change my solidworks models by 0'75" for every additional k-baffle I want to install if I find I want more expansion chambers. Just need to change the sleeve length and everything is golden. I used the same bore diameter ratios that YHM uses as a starting point since I found they are more conservative with their bore relief than others. I added a large blast-chamber as the primary expansion zone to save the baffles from being eaten alive when used in this configuration. The k-baffles rest of a ledge machined into the end of this chamber. I also designed the system to be serviced with only two 1/8" spanner wrenches. Should be easy to change baffles or clean out and easy to reassemble. You can see that stackup in the picture below, and I added a section view to make it easier to see the fitment and threading.

-

Quick question to you more educated firearms folks (you're all criminals, btw); as I've read through the atf.gov site, it seems that if I want to manufacture my own suppressor, all I need is to pay the $200 tax stamp with a Form 1 and wait for the results. Do I have this right? I'm a bored engineer with access to great software and great machining tools, so I have a design all set to go. I just need to know if I go through with it, I'm doing everything legally and properly. I tried to do my homework before I blindly asked my favorite forum, but now I just want a second opinion on my research. As always, thanks in advance (probably to flounder), and I can only hope this becomes an open-carry, SHTF, bug-out, zombie fecal-fest by the third post.

-

I'm kinda surprised that people are surprised by this. When I sign up for a Kroger Plus card, I assume that this is obviously what they're doing with it. I'm not an idiot, why wouldn't they do this? And on the flip side, I know I'm a creature with comfortable habits, so why wouldn't I want someone to just figure them out and give me coupons for the things I know I'm gonna buy already, and not have to go looking for them? If I ever really cared, I would go pay cash for something without my plus card. Not a big deal. TO be honest, most of this shit is kind of obvious if a person would just be observant as well. Not like the computer is doing some magical thing people can't do on their own if they just took the time. As for the dad in that story, computers can see a lot when they don't have denial or invested emotions telling them there's nothing to see here...

-

Chokebot?

-

I'm really a fan of the sprocket idea over the wheel, but as people have said, I like the way the text is presented in the last logo of the first set. If this jew were in charge, I'd use the sprocket design from the bottom set with the text wrapping from the last logo in the first set. I'm liking the direction you took with the dog. Moving away from the angry faces and bulldogs is a good idea. Besides the cliche portion, the one you have now feels more like a shop dog. Just the same quiet, stoic confidence I would want in a mechanic is how I would view a good shop dog. The logo you have now portrays that very well, and it's a smart move, in my opinion.

-

Another orange/red vote.

-

This thread is nothing if not entertaining. I have damn near the same bike with LED's all over the place, and I know this issue very well. You should listen to the guy from Independent (Justin still?), he has the right answer. You're missing the load resistors. If you attach the LEDs and THEY APPEAR TO BE ON ALL THE TIME, BUT ARE JUST PULSING REALLY FAST IF YOU LOOK CAREFULLY, then you have a resistor missing. The timer for the flash circuit is based off of an expected voltage and current draw, and when you change it, the circuit gets all Tom Brady and shits the bed. The resistor must be in parallel with the LEDs, and it's going to be bigger (in terms of size) and get hotter than you might think. I built mine from big load resistors we had lying around the labs, but you should be able to get power resistors at Radio Shack. Again, you're missing the load resistor. I've seen it on my CBR before. Put it in correctly and you'll be fine.

-

I use the Tripage LED hugger for my plate and it's bright as all hell. If anyone were to complain about not being able to see it, I'd have to file a formal complaint about their vision. It's now out of the way but still easier to see at night than a stock CBR. I actually asked a Springboro officer about it before I put it on, just to see if (in his opinion) an officer would pull me over for it, and he said it looked just fine to him. I realize this is by no means a court-worthy approval, I just wanted to know that at least one cop out there thought this was a good solution. I tend to think this is on of the best solutions on the CBRs.

-

"just take the car, they got me the wrong one anyway!" "yea, it's a fucking tragedy..." well done, sir.

-

School Board Says Cougar Mascot Too Offensive To Women

jarvismb replied to TheBrown57's topic in Dumpster

:yourmomjoke: -

ok guys, just went through my info again, and the Remington book, the Lee Book, and the Hodgden site all say that various 55gr rounds should range: Start-MAX ---------------------- 25.0-27.8 (Remington) 24.9-27.5 (LEE) 25.5-27.5 (Hodgden) So now I'm thinking that my loads are ok. Granted these loads are for FMJ/Spire-Point rounds, but I assume that as long as it's not frangible/SinterFire I should be ok with my ballistic-tips, right? Can anyone check their books/sources and tell me if I'm crazy?

-

This is why I checked on here with people that have done this, before I go loading these into my pricey shiny rifle. It's a lot easier to remake the loads than my AR. It is a bit disappointing to see the Remington reloading bible I was using was totally wrong on this. I'm looking at it now and it calls for a starting load of 25.0 grains of Varget on 55gr bullets, with a max load of 27.8 grains. According to this, I would have blown up my rifle in no time.

-

Sounds like a better plan. Thanks again for the heads up.

-

Dammit, I was afraid of that. We got a ton of info that put Varget all over the map, and most of them put the range from 25-27, and only one put them lower (the Hodgden site). I was skeptical to go higher, but a friend told me being in the 25s would be safe, but I didn't know. I'll pull them and redo it. Better to do it twice than mess it up. Thanks.

-

That's a great offer and some sound advice. I'd love to come out for one of those group shoots like last year now that I have something to test. I admit I hadn't thought about the extinguisher, but now that you mention it, I can't believe I didn't have that earlier. Thanks for the tip, I'll be doing that. The recipe so far is: Winchester Brass CCI 400 Primers Hodgden Varget - 25.9 grains Nosler Ballistic Tip - 55gr boat tail C.O.L. - 2.205"

-

Note to self: Charging die may appear harmless, but is way more intense in person. Please set to proper height before use.

-

Well, round one is over, and I've learned a lot. Most importantly, I've learned that 99% of the time, reloading works every time....

-

From the album: AR Build

-

It was Kawi Kid. It had a deer painted on it.

-

'jinu likes men' is on the list. I am Jack's complete lack of surprise.

-

Dayton folks: Where would be a good place for an OR meet and greet?

jarvismb replied to Casper's topic in Daily Ride

My presence will negate this, regardless of venue. Plan accordingly.